|

|

|

ildong wire cloth

Woven Wire Mesh

織金網, Lưới dây đan

|

|

|

|

Woven Wire Mesh

| Usage |

Filter, Strong mesh, Dehydration, etc. |

| Materials |

Stainless Steel Wire 304, 316 Series |

|

| |

| Product demonstration |

|

|

| Related products : Plain weave, twilled weave, plain dutch weave, twilled dutch weave |

|

Plain weave mesh

Plain weaving is the most general way to weave wires by crossing vertical and horizontal wires perpendicularly.

As for the diameter of wires used in a plain weaving, the weaving is possible to same thickness with openings by theoretically, but the diameter of wires less than 80% of openings approx. is suitable due to changes of characteristics during weaving. It is widely used and for wire meshes less than 200 meshes.

Usage : Filter, Earphones, Speakers, etc. Usage : Filter, Earphones, Speakers, etc.

Materials : Stainless Steel Wire 304, 316 Series Materials : Stainless Steel Wire 304, 316 Series

|

| |

|

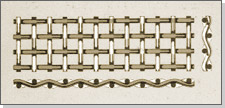

Twilled weave mesh

To weave these mesh, at least more than two vertical and horizontal wires need to be intersected.

A thick wire is available for this weaving than plain weaving. Twilled weaving has advantage of less structural hardening due to small angle of refraction.

Twilled weave is suitable for cases where it requires relatively large loads.

Usage : Filter, Strong mesh Usage : Filter, Strong mesh

Materials : Stainless Steel Wire 304, 316 Series Materials : Stainless Steel Wire 304, 316 Series

|

| |

|

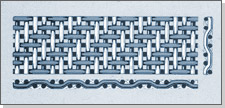

Plain dutch weave mesh

This is a kind of a plain weaving, but weaves wide in vertical and weaves narrow in horizontal to allow liquid or gas passing through openings between both wires.

for these reasons, this kind of weaving is suitable for dissevering functions such as filtration, dehydration and centrifuge. Mesh is counted as the number of openings in the transverse 1 inch.

Usage : Filter, Dehydration Usage : Filter, Dehydration

Materials : Stainless Steel Wire 304, 316 Series Materials : Stainless Steel Wire 304, 316 Series

|

| |

|

Twilled dutch weave mesh

This weaving is the combination of “Twilled weave” and “Dutch weave”, has twice the density compared with “Twilled weaving” because it weaves front and back of the mesh closely on both side. “Twilled dutch weaving” is suitable for the most compact and rugged filtering mesh, and it is possible to weave to few thousands of meshes in an inch.

Mesh is counted as the number of warp wires in the transverse 1 inch.

Usage : Filter, Separatory filter Usage : Filter, Separatory filter

Materials : stainless steel wire 304, 316.. steel grade Materials : stainless steel wire 304, 316.. steel grade

|

| |

|

Standard table of Plain fabrics & Double crimp(■) & Twill(■)

|

|

MESH

|

Diameter

|

OPENNIG

|

OPEN AREA

|

MESH

|

Diameter

|

OPENNIG

|

OPEN AREA

|

|

mm

|

SWG

|

mm

|

SWG

|

|

3

|

1.8

|

15

|

6.667

|

62%

|

18

|

0.23

|

34

|

1.181

|

70%

|

|

3.5

|

1.8

|

15

|

5.457

|

57%

|

16

|

0.45

|

26

|

1.138

|

51%

|

|

4

|

0.9

|

20

|

5.450

|

74%

|

18

|

0.29

|

31

|

1.121

|

63%

|

|

4

|

1.0

|

19

|

5.350

|

71%

|

14

|

0.7

|

22

|

1.114

|

38%

|

|

4

|

1.2

|

18

|

5.150

|

66%

|

16

|

0.5

|

25

|

1.088

|

47%

|

|

4

|

1.4

|

17

|

4.950

|

61%

|

18

|

0.35

|

28

|

1.061

|

57%

|

|

4

|

1.6

|

16

|

4.750

|

56%

|

18

|

0.4

|

27

|

1.011

|

51%

|

|

4

|

1.8

|

15

|

4.550

|

51%

|

16

|

0.6

|

23

|

0.988

|

39%

|

|

5

|

0.8

|

21

|

4.280

|

71%

|

20

|

0.29

|

31

|

0.980

|

60%

|

|

5

|

0.9

|

20

|

4.180

|

68%

|

18

|

0.45

|

26

|

0.961

|

46%

|

|

5

|

1.0

|

19

|

4.080

|

65%

|

20

|

0.35

|

28

|

0.920

|

52%

|

|

5

|

1.2

|

18

|

3.880

|

58%

|

18

|

0.5

|

25

|

0.911

|

42%

|

|

6

|

0.6

|

23

|

3.633

|

74%

|

20

|

0.4

|

27

|

0.870

|

47%

|

|

6

|

0.7

|

22

|

3.533

|

70%

|

24

|

0.23

|

34

|

0.828

|

61%

|

|

6

|

0.8

|

21

|

3.433

|

66%

|

20

|

0.45

|

26

|

0.820

|

42%

|

|

6

|

0.9

|

20

|

3.333

|

62%

|

24

|

0.25

|

33

|

0.808

|

58%

|

|

6

|

1.0

|

19

|

3.233

|

58%

|

20

|

0.5

|

25

|

0.770

|

37%

|

|

7

|

0.6

|

23

|

3.029

|

70%

|

24

|

0.29

|

31

|

0.768

|

53%

|

|

7

|

0.7

|

22

|

2.929

|

65%

|

24

|

0.35

|

28

|

0.708

|

45%

|

|

7

|

0.8

|

21

|

2.829

|

61%

|

28

|

0.23

|

34

|

0.677

|

56%

|

|

7

|

0.9

|

20

|

2.729

|

57%

|

24

|

0.4

|

27

|

0.657

|

39%

|

|

8

|

0.45

|

26

|

2.725

|

74%

|

30

|

0.23

|

34

|

0.617

|

53%

|

|

8

|

0.5

|

25

|

2.675

|

71%

|

30

|

0.25

|

33

|

0.597

|

50%

|

|

8

|

0.6

|

23

|

2.575

|

66%

|

32

|

0.23

|

34

|

0.564

|

50%

|

|

8

|

0.7

|

22

|

2.475

|

61%

|

30

|

0.29

|

31

|

0.557

|

43%

|

|

8

|

0.8

|

21

|

2.375

|

56%

|

32

|

0.29

|

31

|

0.504

|

40%

|

|

8

|

0.9

|

20

|

2.275

|

51%

|

30

|

0.35

|

28

|

0.497

|

34%

|

|

8

|

1.0

|

19

|

2.175

|

47%

|

35

|

0.23

|

34

|

0.496

|

47%

|

|

10

|

0.4

|

27

|

2.140

|

71%

|

40

|

0.18

|

36

|

0.455

|

51%

|

|

10

|

0.45

|

26

|

2.090

|

68%

|

40

|

0.2

|

35

|

0.435

|

47%

|

|

10

|

0.5

|

25

|

2.040

|

65%

|

40

|

0.25

|

33

|

0.385

|

37%

|

|

9

|

0.8

|

21

|

2.022

|

51%

|

50

|

0.14

|

38

|

0.368

|

52%

|

|

10

|

0.55

|

24

|

1.990

|

61%

|

50

|

0.16

|

37

|

0.348

|

47%

|

|

10

|

0.6

|

23

|

1.940

|

58%

|

50

|

0.18

|

36

|

0.328

|

42%

|

|

10

|

0.7

|

22

|

1.840

|

52%

|

50

|

0.2

|

35

|

0.308

|

37%

|

|

9

|

1.0

|

19

|

1.822

|

42%

|

60

|

0.14

|

38

|

0.283

|

45%

|

|

10

|

0.8

|

21

|

1.740

|

47%

|

50

|

0.23

|

34

|

0.278

|

30%

|

|

12

|

0.4

|

27

|

1.717

|

66%

|

60

|

0.18

|

36

|

0.243

|

33%

|

|

12

|

0.45

|

26

|

1.667

|

62%

|

80

|

0.12

|

40

|

0.198

|

39%

|

|

10

|

0.9

|

20

|

1.640

|

42%

|

80

|

0.14

|

38

|

0.178

|

31%

|

|

12

|

0.5

|

25

|

1.617

|

58%

|

100

|

0.1

|

42

|

0.154

|

37%

|

|

12

|

0.55

|

24

|

1.567

|

55%

|

120

|

0.08

|

44

|

0.132

|

39%

|

|

12

|

0.6

|

23

|

1.517

|

51%

|

150

|

0.065

|

45

|

0.104

|

38%

|

|

14

|

0.35

|

28

|

1.464

|

65%

|

165

|

0.053

|

46

|

0.101

|

43%

|

|

12

|

0.7

|

22

|

1.417

|

45%

|

180

|

0.053

|

46

|

0.088

|

39%

|

|

14

|

0.4

|

27

|

1.414

|

61%

|

200

|

0.053

|

46

|

0.074

|

34%

|

|

14

|

0.45

|

26

|

1.364

|

57%

|

250

|

0.04

|

48

|

0.062

|

37%

|

|

12

|

0.8

|

21

|

1.317

|

39%

|

300

|

0.04

|

48

|

0.045

|

28%

|

|

14

|

0.5

|

25

|

1.314

|

52%

|

325

|

0.035

|

48

|

0.043

|

30%

|

|

16

|

0.29

|

31

|

1.298

|

67%

|

350

|

0.035

|

48

|

0.038

|

27%

|

|

16

|

0.35

|

28

|

1.238

|

61%

|

400

|

0.03

|

49

|

0.034

|

28%

|

|

14

|

0.6

|

23

|

1.214

|

45%

|

500

|

0.03

|

50

|

0.026

|

26%

|

|

16

|

0.4

|

27

|

1.188

|

56%

|

|

|

|

|

|

|

| |

|

Standard table of plain dutch weave mesh

|

|

Mesh

|

wire diameter

|

Opening

|

|

Length

|

Width

|

Length

|

Width

|

micron

|

|

12

|

64

|

0.62

|

0.42

|

270~290

|

|

14

|

80

|

0.5

|

0.3

|

220~240

|

|

24

|

110

|

0.38

|

0.27

|

115~125

|

|

30

|

160

|

0.23

|

0.18

|

95~100

|

|

40

|

200

|

0.18

|

0.14

|

70~75

|

|

50

|

250

|

0.14

|

0.11

|

60~63

|

|

| |

|

Standard table of twilled dutch weave mesh

|

|

Mesh

|

WireDiameter

|

Opening

|

|

Length

|

Width

|

Length

|

Width

|

Micron

|

|

20

|

250

|

0.25

|

0.23

|

110 ~120

|

|

32

|

360

|

0.23

|

0.15

|

100 ~ 110

|

|

40

|

400

|

0.18

|

0.14

|

90 ~110

|

|

50

|

500

|

0.14

|

0.11

|

70 ~90

|

|

50

|

600

|

0.14

|

0.09

|

60 ~70

|

|

80

|

800

|

0.12

|

0.07

|

45 ~ 65

|

|

165

|

800

|

0.07

|

0.05

|

24 ~ 26

|

|

120

|

1000

|

0.08

|

0.055

|

27 ~ 28

|

|

165

|

1450

|

0.07

|

0.04

|

16 ~ 18

|

|

270

|

2000

|

0.038

|

0.025

|

11 ~ 13

|

|

325

|

2300

|

0.038

|

0.025

|

8 ~ 9

|

|

325

|

2400

|

0.035

|

0.025

|

7 ~ 8

|

|

450

|

2750

|

0.025

|

0.02

|

6 ~ 7

|

|

510

|

3600

|

0.025

|

0.015

|

5 ~ 6

|

|

| |

|

Classify

|

General

|

Order

|

Remarks

|

|

Mesh

|

For plain weave, up to 500Mesh (Refer to table)

For twilled dutch weave, up to 2,400Mesh

(Refer to table)

|

For plain weave, all Mesh between 3~500Mesh

For twilled dutch weave,

all Mesh (Refer to table)

|

Below than 4Mesh, Prefer to crimp weaving

|

|

Diameter Of Wire

|

0.02 ~ 5mmΦ

(Refer to table)

|

All kinds of diameter between 0.02~5mmΦ

|

Above than 5mm, Prefer to crimp weaving

|

|

Width

|

1M 1.2M 1.5M 2M 2.5M Width(1M Width is Basic)

|

from 1.0m to 2.5m Width

|

|

|

Length

|

30M

|

All length possible (Depend on the product)

|

|

|

Materials

|

Stainless steel (304), Iron, Bronze, Brass

|

Stainless steel (304, 316, 314, 310, 430, etc.), Iron chromium, Nickel, Monel, Inconel, Molybdenum, Tungsten, Titanium, Gold, Silver, Pt.

|

Stainless steel (316, 314), Iron chromium, Nickel(Retention Stocks Available)

|

|

| |

|

.gif)

|

| |

|

Mesh Mesh

It is a unit displaying mesh of stainless steel wire cloth and is the number of meshes between 1 inch (25.4mm). Generally, stainless steel wire mesh displays horizontal first and vertical later.

The picture beside shows 4 × 4 mesh (Diameter 1.2mm)

|

| |

|

Dia. of Wire Dia. of Wire

Diameter of wire composing a woven wire mesh.

Use a unit of mm or use number by the diameter table of wire.

Weft wires - Vertical wire of mesh(Length Direction)

Warp wires - Horizontal wire of mesh( Width Direction)

|

| |

|

Opening Opening

Opening is the width between the wire and wire comprising wire mesh and is calculated by the formula below .

Opening(mm) = 25.5 mm ÷ Mesh – Diameter of Wire(mm)

Ex) 25.4 ÷ 4 – 1.2 = 5.15 mm

|

| |

|

Open Area Open Area

It means the percentage of space area of the mesh.

Open Area(%) = (Opening)²÷ (Opening + wire diameter)² × 100

Ex) (5.15)² ÷ (5.15 + 1.2)² x 100 = 65.77(%)

Even in the case of the same mesh, an “open area” can be changed in accordance with the difference of diameter of wire.

|

|

| |

.gif) .gif) |

|

|

|

| |

|

|